Injection molds are critical in manufacturing. Traditional mold manufacturing faces challenges in efficiency and cost. Resin 3D printing, as an innovative solution, has great potential in design freedom and production cycle. How can this technology optimize injection molds? What business opportunities will it bring? This article will explore in depth.

Resin 3D printing has demonstrated advantages in optimizing injection molds, such as complex cooling and rapid iteration. However, how the technology translates into commercial value is even more critical. Next, we will focus on the commercial value of resin 3D printing in shortening cycles, reducing costs, and improving quality.

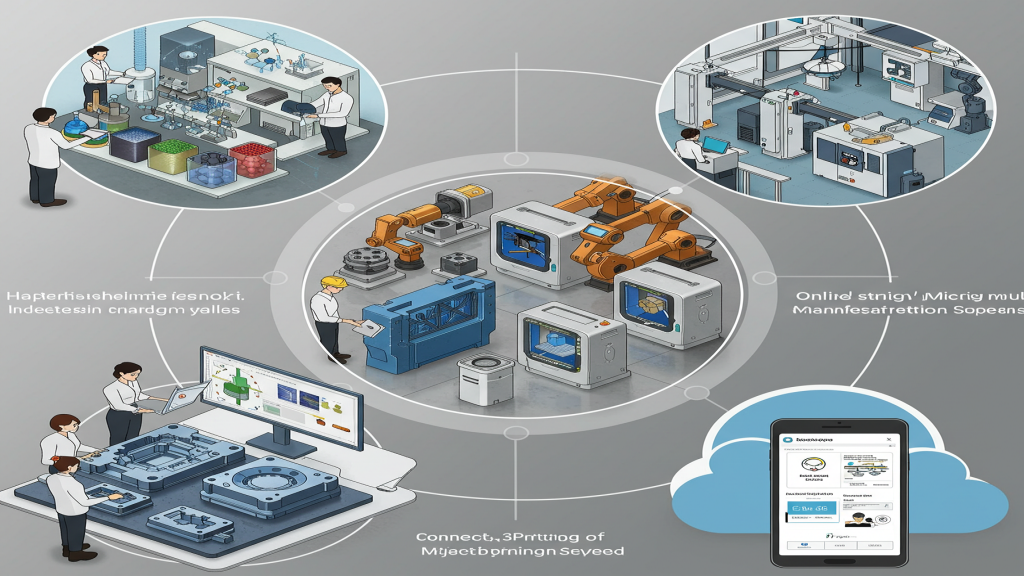

How Does 3D Printing Innovate Injection Molds?

Through the unique advantages of additive manufacturing, resin 3D printing technology can directly build mold structures that are difficult to achieve with traditional methods, thereby fundamentally changing the design concepts and production processes of injection molds.

- Complex Geometry: Resin 3D printing can manufacture complex internal structures and special curved surface molds that are difficult to achieve with traditional processes.

- Design Iteration: Resin 3D printing significantly accelerates the iteration cycle of mold design verification and customized production.

- Functional Integration: Resin 3D printing can integrate functions such as conformal cooling and utilize diversified materials to improve mold performance.

- Cost and Time: For specific needs, resin 3D printing helps reduce mold manufacturing costs and shorten production time.

How Does 3D Printing Optimize Mold Performance and Cost?

Compared with traditional mold manufacturing processes, injection molds empowered by resin 3D printing technology not only achieve breakthroughs in design flexibility and functional integration but also demonstrate significant advantages in improving production efficiency and controlling operating costs.

- Cooling Performance: 3D printed molds achieve more efficient and uniform cooling through conformal cooling, improving production efficiency and product quality.

- Iteration and Customization: 3D printing accelerates mold iteration and customization, shortening the development cycle and meeting small-batch needs.

- Manufacturing Costs: In certain situations, 3D printing can effectively reduce the manufacturing costs and time for complex and small-batch molds.

- Functional Integration: 3D printing helps molds integrate more functions, optimizing overall performance and intelligence level.

What are the Key Steps for Optimizing Molds with 3D Printing?

Successfully using resin 3D printing to optimize injection molds requires careful consideration and precise execution in multiple stages, including design, material selection, printing process, and post-processing, to ensure that the performance and service life of the mold meet actual production needs.

- Requirement Design: In-depth understanding of product and mold requirements, and use 3D printing to optimize mold design.

- Material and Process: Select appropriate resin materials and 3D printing processes based on injection molding and mold requirements.

- Printing and Post-processing: Precisely control the printing process and perform necessary post-processing to ensure mold quality.

- Testing and Validation: Conduct thorough testing and validation of 3D printed molds to ensure they meet production requirements.

Application of 3D Printing in Mold Optimization

|

Application Area |

Limitations of Traditional Molds |

3D Printing Optimization |

Performance/Cost Benefits |

| Cooling Systems | Limited design, inefficient cooling | Complex conformal cooling channels | Shorter cycles, improved quality, less warpage |

| Complex Structures | Difficult to achieve special geometries | Direct manufacturing of complex internal/external structures | Enables innovative designs, enhances functional integration |

| Design Iteration | Long cycle, high cost | Rapid prototyping and modification, easy customization | Accelerated development, reduced low-volume costs |

| Rapid Manufacturing | Slow response to small-volume needs | Direct printing of molds or inserts | Fast delivery, reduced costs in specific scenarios |

The Value of 3D Printing in Injection Molds

Resin 3D printing technology will show a more vigorous development trend in the field of injection molds. With the advancement of materials science, resin materials with higher strength, higher temperature resistance, and greater functionality will be developed, further broadening the application range of 3D printed molds. At the same time, faster and more precise printing equipment and more intelligent software solutions will emerge, improving the manufacturing efficiency and reliability of molds.

1.High-Performance Materials: Stronger, more durable, and more functional resins will broaden the application range of 3D printed molds.

2.Intelligent Automation: More intelligent and faster equipment and automated processes will improve mold manufacturing efficiency and reliability.

3.Customization and Flexibility: 3D printing will deepen the customization and flexible manufacturing of injection molds, enhancing corporate competitiveness.

4.Service Model Innovation: 3D printing-based mold service models will lower the barrier to entry and promote the construction of an industrial ecosystem.

Conclusion

Resin 3D printing technology is revolutionizing the design and manufacturing of injection molds in an unprecedented way. It significantly improves the performance and cost-effectiveness of molds by enabling complex geometries, accelerating design iterations, integrating diverse functions, and reducing costs and time in specific scenarios.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Apr-27-2025